Latest innovations / Nonwoven & specialties

Foam forming and extensible moulded webs

Binder for foam forming and moulded fibre

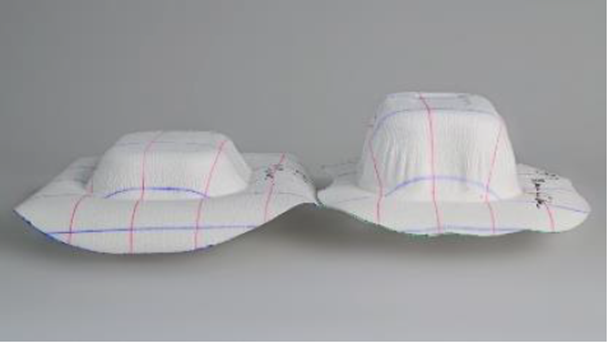

CHP 557 can be used as a foaming agent to create foam-formed and wet-laid webs. Foam forming enables the use of longer cellulose-based fibers, rather than plastic-based fibers. In VTT’s Piloting Alternatives for Plastics project, CHP 557 was used to bind cellulose-based fibers. When CHP 557 was added to the fibre web, the extensibility was enhanced. This enabled forming deeper trays. Click here for more information about CHP 557.

Piloting Alternatives for Plastics

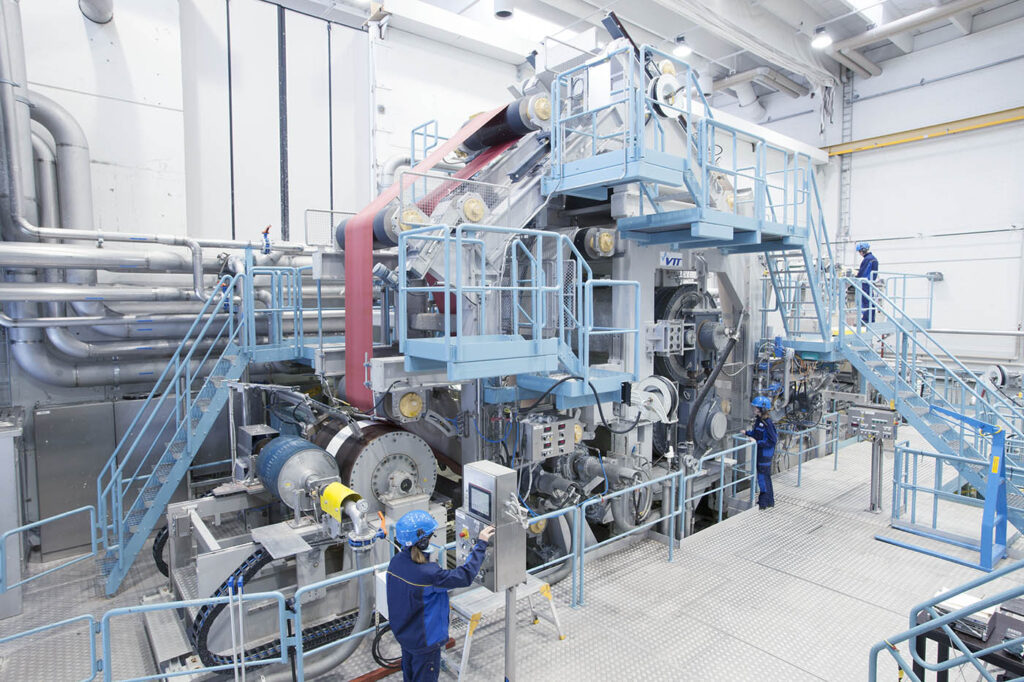

In VTT’s Piloting Alternatives for Plastics, a jointly funded ERDF project, plastic fibers have been replaced by cellulose-based fibers. The development work has been conducted as a part of a research program, where VTT in co-operation with 54 companies and Regional Council of Central Finland have up-scaled promising alternatives for plastic products. Click here to find out more about the research program.

Want to know more?

Whether you have a question about products, pricing, or anything else, our team is ready to answer all your questions

Ask more

Tuija Andersson

Director

+358 50 328 2970

[email protected]

Kimmo Huhtala

Technical Sales Manager

Paper and Packaging

Nonwoven and Specialties

+358 50 409 9314

[email protected]