Sustainable and safe food packaging – presented in Specialty Papers Europe 10.4.2019 in Berlin by Mia Ahokas

The European Union parliament just passed a vote on banning a wide-range of single-use plastic items by 2021. Consumers are encouraging the food industry to rethink and to focus on safe and sustainable solutions.

Our Water Based Barrier Coating CHP BAR series is an answer to this new demand replacing

- polyethylene (PE)

- wax

- fluorocarbon

When introducing new materials to existing technologies you encounter also new challenges like blocking in

- reel winding

- pile of sheets in converting

- during storage and transport

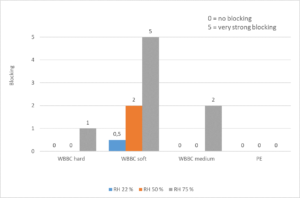

The main challenge in application of WBBCs is the blocking phenomenon. Blocking is an undesired adhesion between two surfaces. It can occur for example in a reel in winding, in a pile of sheets or in converting processes.

These interactions are influenced by factors such as

- temperature

- pressure

- film roughness

- thickness and hardness

- friction

- moisture

With our developed calender blocking test method we were able to efficiently identify blocking tendency of various different WBBC formulations.

Moisture plays a crucial role in blocking of WBBCs. Water acts as a plasticizer making the barrier film softer and enabling adhesion to the contact surface. Changing technology from PE into repulpable & recyclable & biodegradable solutions requires a change in process as well as in thinking.

Figure 1 shows that PE is less sensitive against the effect of moisture. This is where you need to be clever:

By using calender blocking test method we can design WBBC board solutions that are monomaterial, repulpable, recyclable in normal board recycling – and of course more sustainable without PE, wax or fluorocarbon.

Figure 1: Blocking barrier side against reverse side at different relative humidities.